Manufacturing Cost Estimation Software: Your Key to Precision and Profit

Manufacturing cost estimation software (CES) is a powerful tool that streamlines the complex/cumbersome process of calculating production costs. By leveraging advanced algorithms and defined data, CES empowers you to:

- Gain Comprehensive Cost Visibility: Accurately assess the true cost of your products, factoring in raw materials, machining time, labor rates, freight, tooling, overhead, and other critical variables.

- Make Data-Driven Decisions: Input your specific parameters, and the software instantly generates precise cost estimates for both individual components and finished products. This enables you to optimize supplier selection, negotiate better deals, and identify cost-saving opportunities.

- Boost Efficiency and Accuracy: Eliminate the time-consuming and error-prone task of manual calculations. CES delivers results swiftly and with unparalleled accuracy, freeing your team to focus on strategic initiatives.

Universal Applicability

Manufacturing Cost Estimation Software (CES) is not industry-specific. Whether you are in automotive, electronics, construction, or any other manufacturing sector, this software can be tailored to your unique needs.

Modules Covered in Our Manufacturing Cost Estimation Software

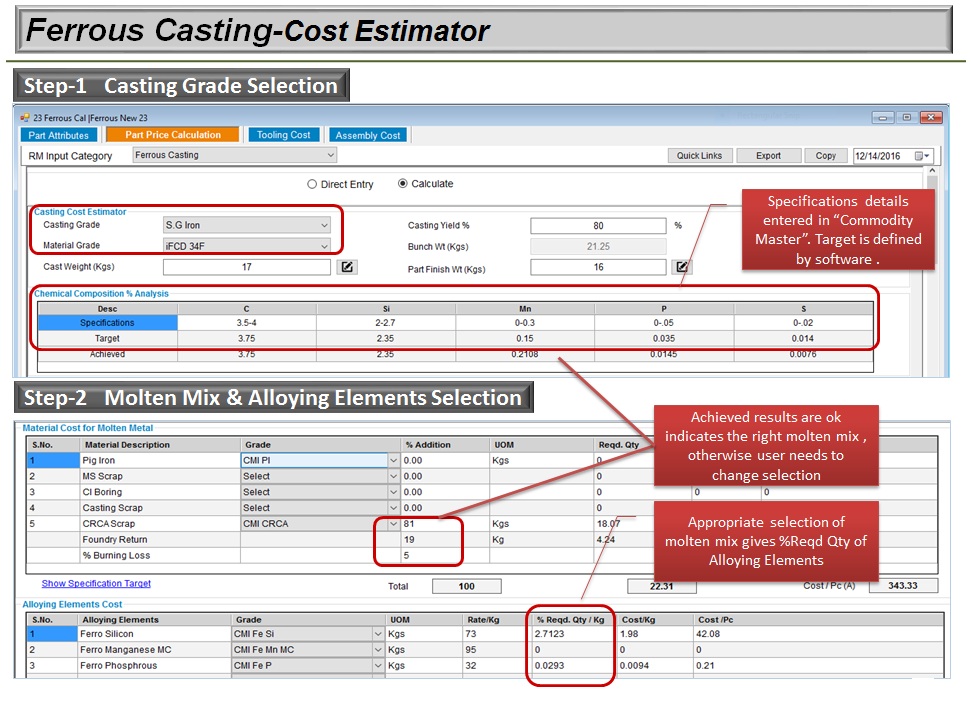

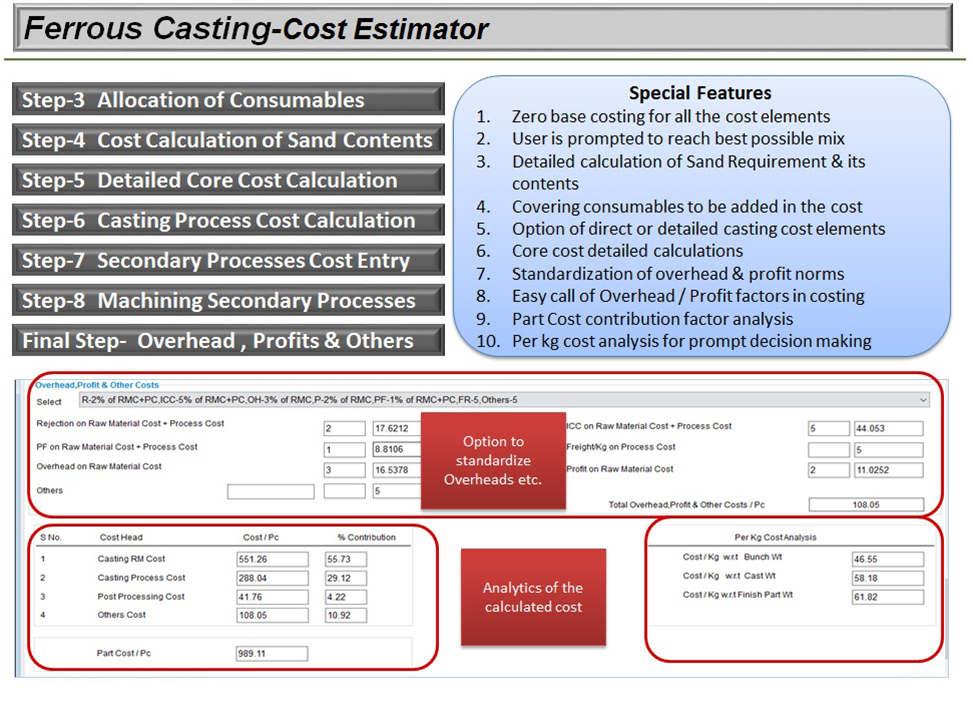

1. Ferrous Casting Cost Estimation

Ferrous casting is a metal working moulded as molten into the custom shape onto die-cast uses in different industries. These costs are also a significant part of determining expenses for ferrous casting, which is key to enabling businesses to streamline production processes, maintain competitive pricing and profitability. This is where CostMasters, a multi-experienced cost estimating software score valuable solutions and insights with you to enable the same.

Estimating the cost of ferrous casting as accurate possible is a necessity for businesses to survive and remain profitable. One such advanced software tool for cost estimation is offered by CostMasters, which should enable you to do just that. Our software can help you increase process efficiency, cut costs and grow your bottom line.

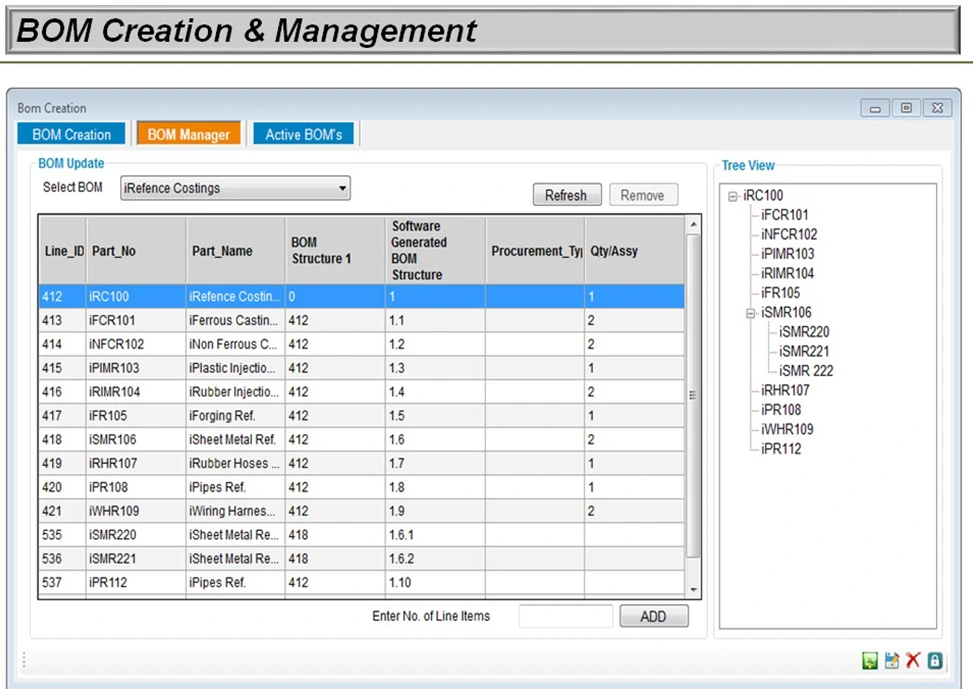

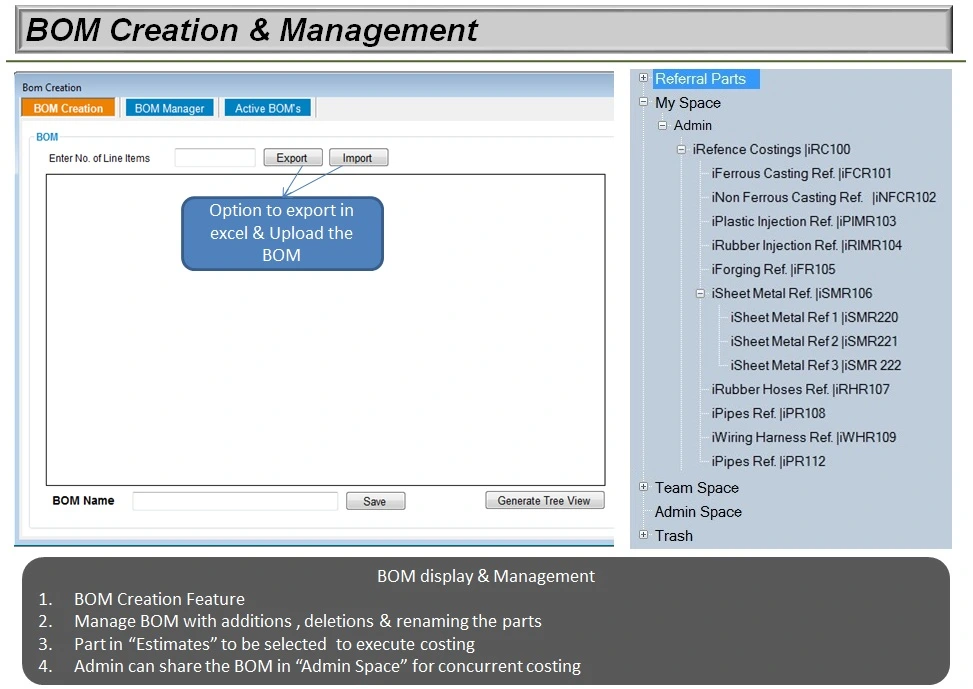

2. BOM Creation & Management

The BOM is critical to manufacturing operations. A clearly laid-out BOM captures the entire range of components, assemblies and sub-assemblies needed to manufacture a finished product. The robust Feature-Rich BOM creation and management processes are optimized with the Comprehensive Cost Estimation Software from CostMasters.

Also, this BOM creation and management by CostMasters is the software for which any manufacturer would vouch as it provides a greater control over all internal functions of an enterprise. By managing your BOMs correctly, you can increase efficiency, generate more accurate information and streamline the manufacturing of a particular product.

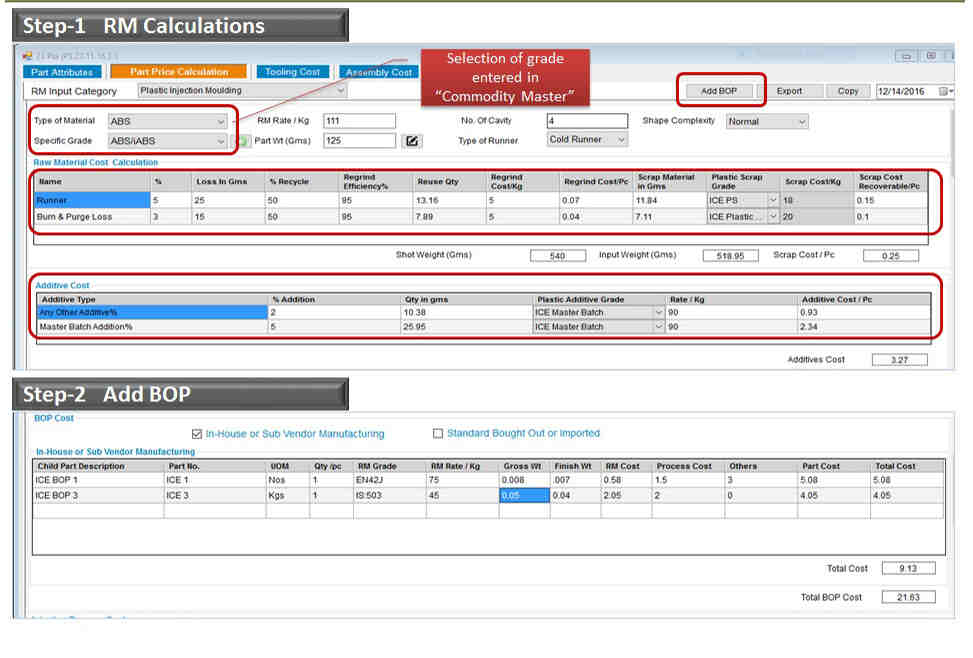

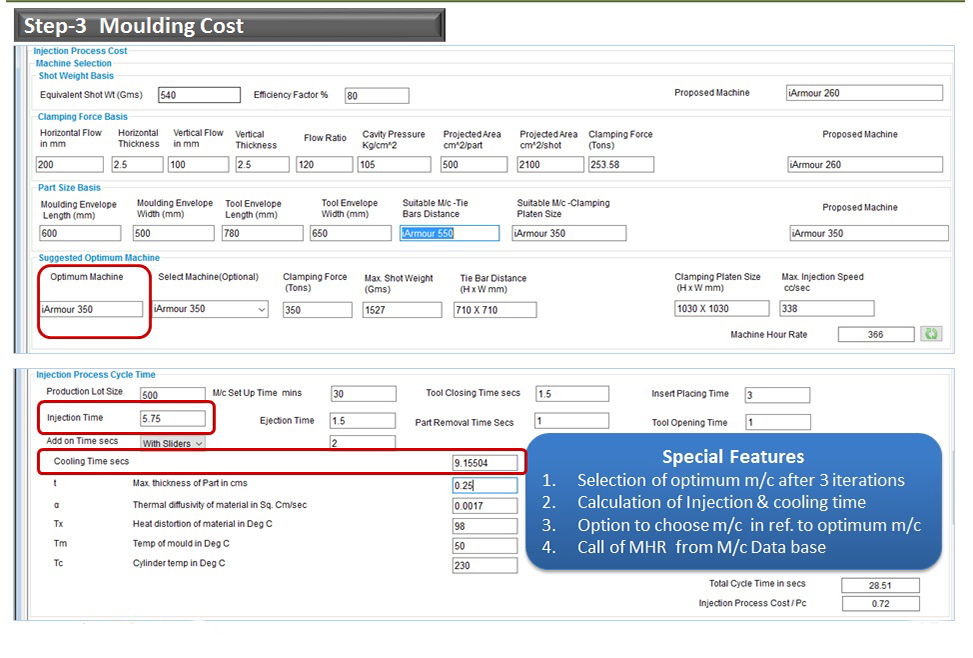

3. Plastic Injection Moulding

Plastic injection molding is a manufacturing process in which the molten plastic is injected into a closed mold which when cooled forms a product of a specific shape. This process is widely used to manufacture a variety of plastic products, such as automobile parts, electronic devices, household items, and toys.

Plastic injection molding is an important manufacturing process that is used in a variety of industries. CostMasters’ Manufacturing Cost Estimation Software can help you accurately estimate the costs of your plastic injection molding processes, allowing you to increase the profitability of your business.

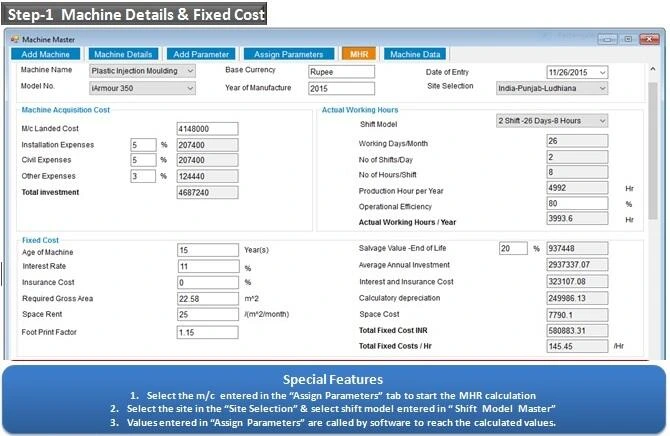

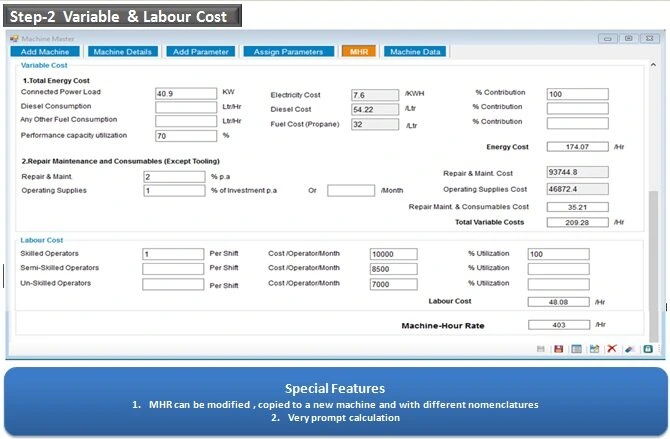

4. Machine Hour Rate Cost Calculation

CostMasters’ Machine Hour Rate Calculation software helps you calculate the hourly rate of your machines. This software takes into account essential information about your machines such as machine cost, usage lifetime, maintenance costs and other factors.

The Benefits of Manufacturing Cost Estimation Software

- Elimination of Manual Calculations: Reduce the risk of human error and free up valuable resources.

- Enhanced Accuracy: Ensure precise cost estimates for better financial forecasting and planning.

- Cost Reduction: Identify and address cost drivers throughout the production process.

- Comprehensive Analysis: Gain insights into cost variations based on factors like raw material sourcing, processes and labor rates in different locations.

By harnessing the power of manufacturing cost estimation software, you can transform your procurement and production processes, driving efficiency, accuracy, and profitability to new heights.

In today’s fiercely competitive manufacturing landscape, the ability to accurately and swiftly estimate production costs is paramount. As product development cycles shrink and market demands intensify, companies must harness advanced manufacturing cost estimation capabilities to remain profitable and outpace rivals.

Why Staying Ahead is Non-Negotiable:

Manufacturers who cling to outdated methods risk being left behind. Without the precision and agility afforded by modern cost estimation tools, they will struggle to compete in the global marketplace.

The Evolution of Cost Estimation:

Gone are the days when manufacturing cost estimation relied solely on experience and “rules of thumb.” Today, computer-aided cost estimation (CACE) software has revolutionized the industry, streamlining even the most intricate calculations and delivering unparalleled accuracy.

Key Advantages of Embracing CACE:

- Accelerated Timelines: Respond swiftly to customer inquiries and deliver quotes faster than ever before.

- Enhanced Accuracy: Eliminate guesswork and confidently make informed decisions based on precise cost data.

- Increased Profitability: Identify cost-saving opportunities throughout the production process, maximizing your bottom line

By embracing cutting-edge cost estimation solutions, manufacturers can unlock a new level of competitiveness, ensuring they remain at the forefront of their industry in an ever-evolving global landscape.

CostMasters’ ICE: Your Strategic Advantage for Data-Driven Manufacturing Cost Optimization

Introducing ICE, India’s pioneering zero-base costing software that empowers manufacturers to achieve unparalleled cost visibility and control.

Why Choose CostMasters’ ICE?

- Comprehensive Cost Calculation: ICE meticulously calculates the cost of each part, stores historical data for future reference, simplifies amendment, and provides actionable analytical insights.

- Complete Cost Coverage: The software encompasses all cost factors and their impact on the final product, ensuring no element is overlooked.

- Instantaneous Reporting: Generate time-saving reports in seconds, including raw material impact analysis, price change histories, part cost calculations, consumption data, and commodity-specific spending breakdowns.

- Unmatched Traceability and Transparency: Gain a crystal-clear understanding of your manufacturing costs, enabling better decision-making and optimization.

- Agile Cost Amendments: Easily update and modify cost estimates as market conditions, commodity or manufacturing processes change, ensuring your revised data remains accurate and relevant.

With a proven track record since 2017, CostMasters is a trusted leader in manufacturing cost estimation software. ICE seamlessly integrates with your existing systems, digitizing your methodologies and centralizing all cost-related information within a single platform.

Getting Started with ICE(Intelligent Cost Estimator)

- Availability: Intelligent Cost Estimator is a web-based application installed on production server of client.

- Walkthrough/Tutorial: Upon deal closure, single point of contact will be assigned from CostMasters side who will carry forward software implementation. It includes trainings through MS teams/Google meets and every query will be addressed for quick resolution

Conclusion

ICE is poised to revolutionize the way we approach manufacturing industry. With its innovative features, intuitive design, and commitment to user experience, it is definitely an application worth exploring. Say goodbye to error-prone Excel sheets and embrace a future of data-driven cost control with ICE